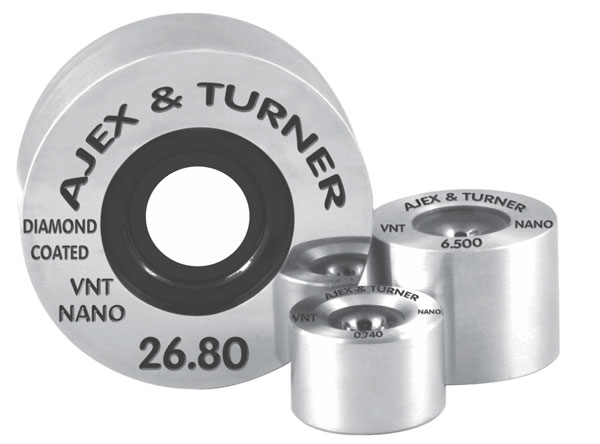

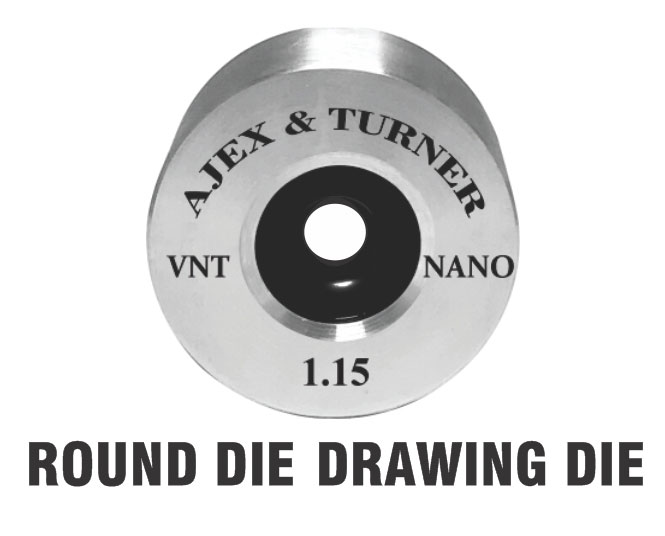

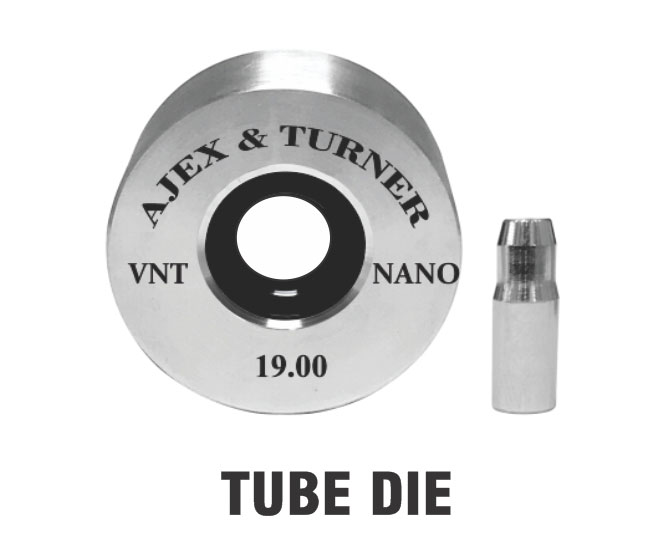

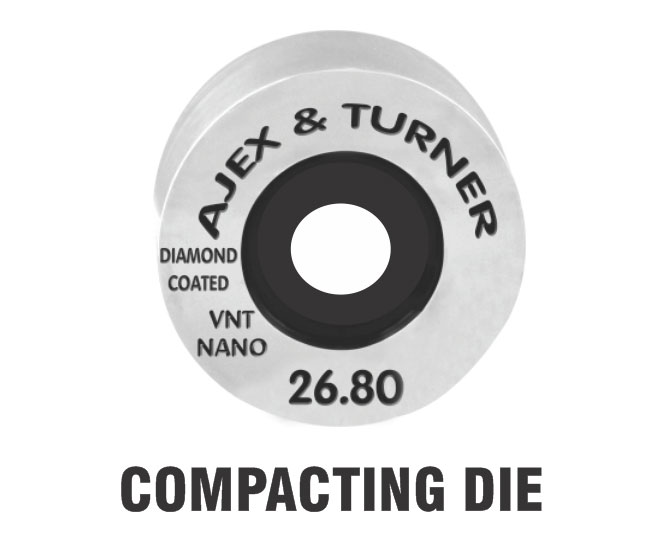

Ajex & Turner have come up with the new revolutionary Vitrified Nano-crystalline Technology which has completely changed the traditional way of wire drawing. The Prospects of Vitrified Nano-technology will definitely put huge impact in near future and will save material and manufacturing cost for Wire & Cable companies| Welding Wires | Low & High Carbon |Stainless Steel Industries around the globe. Our R & D team has developed state of the art diamond coated dies called as VNT Nano. Same VNT nano dies can be used for compacting Copper and Aluminium stranding |Bunching | Compacting | 50mm to 2000sqmm for ENERGY & METAL 3 to 4% SAVING. Customers who use VNT Nano-Dies for drawing Aluminium and Alloys report excellent results in which the material strength is enhanced and in many cases the electrical resistance is reduced. Now our company have developed sector shape & other shape dies in VNT nano crystalline diamond.

VNT Nano dies are made with Multi layer coatings of Nanocrystalline Diamond through Vapor deposition on carbide base metal, which provides extremely smooth surface with immensely low friction.

Nanocrystalline diamond coatings have been used extensively to improve the properties of surfaces for manufacturing processes due to favorable material properties such as high hardness improved wear resistance, excellent thermal conductivity chemical inertness and low coefficient of friction.

Using VNT nano dies, the user will get bright wire surface and better production than TC or PCD. It is found very cost effective, bright surface on the wire, low energy consumption, metal saving etc. These are highly recommended for bright and high quality surface finish.

Our VNT Nano dies which is a development since 2013 and are very much appreciated all over the world by the wire and cable industry for drawing and compacting for copper || aluminium || alu alloy ||stainless steel || high | low carbon || welding || brass wire || Copper Tube etc. Some of the benefits of VNT Nano dies are as follows:

SUCCESSFUL SHOW AT WIRE SOUTHEAST ASIA HELD IN BANGKOK

SUCCESSFUL SHOW AT WIRE SOUTHEAST ASIA HELD IN Mumbai Exhibitions 2018